How is shilajit extracted?

Shilajit, known as "the destroyer of weakness" in Sanskrit, is a complex organic substance that seeps from layers of rock in mountainous regions, particularly the Himalayas, Altai, and Caucasus mountains. This blackish-brown resinous material has been valued in traditional medicine systems for centuries due to its rich mineral content and therapeutic properties. The transformation of raw shilajit into a commercially viable shilajit extractinvolves a sophisticated multi-stage process that preserves its bioactive compounds while removing impurities. This article provides an in-depth look at the intricate extraction processes that turn this natural exudate into a potent health supplement.

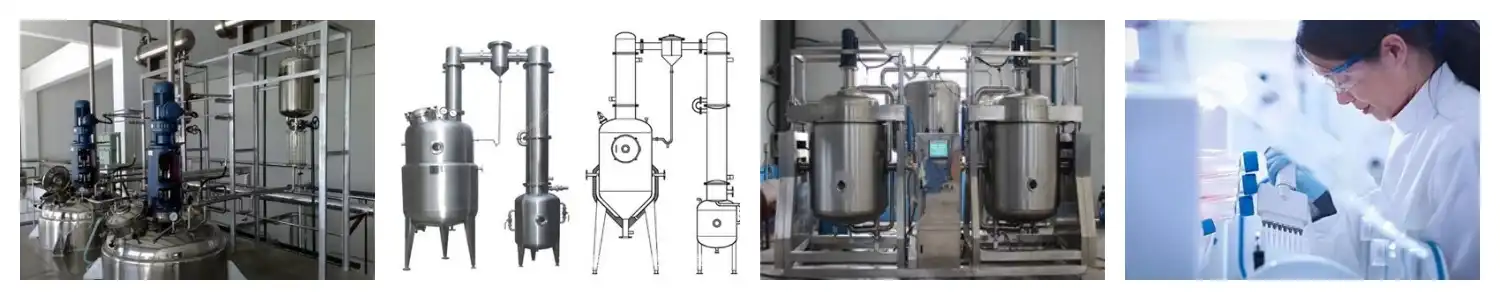

The production of high-quality extract requires meticulous attention to detail throughout the extraction journey. Modern manufacturers employ scientific methods that honor traditional practices while incorporating contemporary quality standards. The extraction process typically unfolds in three main phases: raw material collection and preliminary purification, extraction and concentration of active ingredients, and final forming and quality control.

Raw Material Collection and Preliminary Purification

The journey of shilajit extract begins with sourcing raw material from its natural habitat. Collection typically occurs during summer months when higher temperatures cause the resin to exude from rock crevices in mountainous regions at altitudes between 1000-5000 meters. Experienced collectors identify authentic shilajit deposits by their characteristic appearance, texture, and slightly bitter taste with a distinctive smell. The collection process is labor-intensive and requires significant expertise to distinguish genuine shilajit from similar-looking substances that lack medicinal properties.

After collection, the raw shilajit undergoes preliminary cleaning to remove obvious physical impurities such as rock fragments, plant debris, and soil particles. This initial cleaning phase is critical as it directly impacts the quality of the final shilajit extract. Traditionally, local collectors would soak the raw material in mountain spring water and manually remove visible contaminants. Modern manufacturers have refined this process while maintaining its fundamental principles.

The pretreatment stage also involves microbial assessment and initial stabilization. The raw material is tested for microbial contamination and subjected to controlled drying to reduce moisture content to optimal levels, typically between 15-20%. This careful moisture reduction helps prevent microbial growth while preserving heat-sensitive compounds. Some manufacturers employ low-temperature dehydration techniques that maintain temperatures below 40°C to protect thermolabile bioactives within the shilajit matrix.

Following initial cleaning and drying, the material undergoes a more intensive purification process. This often involves sequential filtration through progressively finer media to remove microscopic impurities. The filtration stages may utilize materials ranging from natural cotton and silk to modern membrane filtration systems, depending on the manufacturer's protocols. This progressive filtration ensures the removal of insoluble matter while retaining the water-soluble bioactive components that contribute to shilajit extract's therapeutic properties.

Another critical aspect of preliminary purification is the removal of potential heavy metal contaminants. Given that shilajit forms through the decomposition of plant matter in mineral-rich environments, it can sometimes contain excessive levels of certain metals. Reputable manufacturers employ techniques such as ion-exchange processes or complexation methods to selectively remove heavy metals while preserving beneficial mineral content in the shilajit extract.

Extraction and Concentration of Active Ingredients

The core extraction process transforms the pretreated shilajit material into a concentrated form rich in bioactive compounds. This stage begins with solvent selection—a critical decision that influences both the yield and composition of the final shilajit extract. While water serves as the primary solvent in traditional processing, modern extraction methodologies may incorporate controlled aqueous-alcoholic solvent systems to optimize the extraction of both hydrophilic and moderately lipophilic components.

The extraction process typically employs temperature-controlled conditions to facilitate the dissolution of active compounds. Research indicates that moderate temperatures between 40-60°C provide optimal conditions for extracting key components like fulvic acid without degrading heat-sensitive compounds. The material-to-solvent ratio is carefully calibrated, typically ranging from 1:4 to 1:10 depending on the raw material quality and desired concentration of the final product. This ratio ensures efficient extraction while minimizing solvent usage.

Time represents another crucial variable in the extraction process. Extended contact between the shilajit material and the extraction medium allows for thorough dissolution of complex bioactive molecules. Industrial-scale production often employs dynamic extraction methods such as percolation or counter-current extraction to enhance efficiency. These techniques create a concentration gradient that drives continuous dissolution of compounds from the solid material into the extraction medium.

Following the primary extraction, the liquid extract undergoes concentration to remove excess solvent and increase the potency of bioactive compounds. This concentration phase typically employs low-temperature evaporation under reduced pressure (vacuum evaporation) to protect thermolabile constituents. Advanced facilities may utilize technologies such as thin-film evaporators or spray drying with protective excipients to minimize thermal exposure during concentration of the shilajit extract.

A distinguishing feature of premium shilajit extract production is the implementation of standardization procedures during the core process. Manufacturers monitor and adjust processing parameters to achieve consistent levels of marker compounds, particularly fulvic acid, which typically serves as the primary standardization marker. Real-time process analytical technologies allow for continuous monitoring of extract composition and enable adjustments that ensure batch-to-batch consistency in bioactive content.

Forming and Quality

The final stage in shilajit extract production transforms the concentrated extract into its market-ready form through carefully controlled post-processing techniques. This phase begins with adjusting the concentrated extract to precise specifications regarding active ingredient content, particularly fulvic acid levels, which quality manufacturers standardize to consistent percentages (commonly 50% for premium products). This standardization ensures that each batch delivers reliable therapeutic effects.

Drying represents a critical operation in this stage, with the method selected significantly influencing the final product characteristics. Spray drying produces a fine, free-flowing shilajit extract powder with excellent solubility characteristics, while freeze-drying (lyophilization) better preserves temperature-sensitive compounds but at higher production costs. Some manufacturers employ vacuum belt drying for larger particles with controlled moisture content. The selection of drying technology balances considerations of bioactive preservation, physical properties, and production efficiency.

For powdered shilajit extract products, particle size reduction and standardization follow the drying process. Controlled milling operations reduce the dried extract to specific particle size distributions, typically achieving the 80-mesh specification mentioned in quality standards. This controlled particle size ensures consistent dissolution rates and improves the material's handling properties during subsequent formulation into capsules, tablets, or other dosage forms.

Quality control represents the cornerstone of the post-processing stage. Each batch of finished shilajit extract undergoes rigorous analytical testing according to established specifications. These assessments typically include:

• Identity confirmation through spectroscopic fingerprinting (FTIR or UV-Vis analysis)

• Potency determination via quantification of marker compounds (HPLC analysis of fulvic acid content)

• Physical property assessment (moisture content, solubility, particle size distribution)

• Microbial testing to ensure adherence to pharmacopeial limits

• Heavy metal analysis to confirm levels below regulatory thresholds

• Stability assessment under accelerated conditions to predict shelf-life

The final shilajit extract undergoes protective packaging designed to maintain product integrity throughout its shelf life. Packaging systems typically include moisture-resistant barriers, oxygen scavengers, and light-protective materials that shield the product from environmental factors that could trigger degradation. Each package receives appropriate labeling with batch identification, manufacturing date, and expiration information to ensure traceability.

Throughout the entire extraction process, from raw material collection to final packaging, documentation plays a vital role in quality assurance. Manufacturers maintain detailed records of process parameters, in-process controls, and final test results. This comprehensive documentation supports batch release decisions and provides evidence of compliance with Good Manufacturing Practices (GMP) standards that regulatory authorities increasingly require for dietary supplement ingredients.

Rebecca: Pure Shilajit Extract Manufacturer

At Rebecca, we specialize in producing premium shilajit extract with consistent quality and exceptional purity. Our products feature:

Active ingredients: fulvic acid

Specification: fulvic acid 50%

Appearance: Yellow brown Fine Powder

Mesh size: 80 Mesh

Test Method: HPLC

Our manufacturing process adheres to the highest quality standards, ensuring you receive a high-quality extract that delivers reliable results for your formulations. We maintain strict control throughout each production stage, from careful raw material selection to advanced extraction techniques and comprehensive quality testing.

For more information or to place an order, please reach out to us at information@sxrebecca.com. Our team of experts is ready to assist with your specific requirements and provide the documentation you need to support your product development.

References

1. Carrasco-Gallardo, C., Guzmán, L., & Maccioni, R. B. (2012). Shilajit: a natural phytocomplex with potential procognitive activity. International Journal of Alzheimer's Disease, 2012, 674142.

2. Meena, H., Pandey, H. K., Arya, M. C., & Ahmed, Z. (2010). Shilajit: A panacea for high-altitude problems. International Journal of Ayurveda Research, 1(1), 37-40.

3. Mittal, P., Kaushik, D., Gupta, V., Bansal, P., & Khokra, S. (2009). Therapeutic potentials of "Shilajit rasayana"—A review. International Journal of Pharmaceutical and Clinical Research, 1(2), 47-49.

4. Stohs, S. J. (2014). Safety and efficacy of shilajit (mumie, moomiyo). Phytotherapy Research, 28(4), 475-479.

5. Wilson, E., Rajamanickam, G. V., Dubey, G. P., Klose, P., Musial, F., Saha, F. J., Rampp, T., Michalsen, A., & Dobos, G. J. (2011). Review on shilajit used in traditional Indian medicine. Journal of Ethnopharmacology, 136(1), 1-9.