Lycopene Extraction Procedure

Lycopene extraction is a crucial process in obtaining high-quality lycopene extract powder, a potent antioxidant with numerous health benefits. This procedure involves carefully selecting solvents, optimizing temperature and time parameters, and employing advanced purification techniques. The extraction of lycopene from tomatoes and other lycopene-rich sources requires precision and expertise to ensure maximum yield and purity.

English name: tomato extract

Latin Name: Lycopersicon esculentum

CAS No.: 502-65-8

Molecular formula:C40H56

Molecular Weight: 536.88

Active ingredients: lycopene

Specification: 5%~98%

Use Part : fruit

Appearance: Dark red powder

Mesh size:80 Mesh

Test Method: HPLC

Solvent Selection: Key to Efficient Extraction

Organic vs. Green Solvents for Lycopene Extraction

The choice between organic and green solvents plays a pivotal role in lycopene extraction efficiency. Traditionally, organic solvents like hexane and ethyl acetate have been widely used due to their high extraction yields. However, the growing demand for eco-friendly processes has led to the exploration of green solvents. Supercritical CO2, for instance, offers a promising alternative, leaving no residual solvent in the final lycopene extract powder.

Green solvents, such as ethanol and isopropanol, present advantages in terms of safety and environmental impact. These solvents are generally recognized as safe (GRAS) by regulatory bodies, making them attractive for use in health supplements and functional foods. Nevertheless, their extraction efficiency may be lower compared to conventional organic solvents, necessitating optimization of extraction parameters.

Optimizing Solvent Polarity for Maximum Yield

The polarity of the solvent significantly influences lycopene extraction yield. Lycopene, being a non-polar molecule, is more soluble in non-polar or slightly polar solvents. Mixtures of solvents with varying polarities can be employed to enhance extraction efficiency. For example, a combination of hexane and ethyl acetate has shown promising results in maximizing lycopene yield while maintaining product purity.

Solvent polarity optimization involves careful consideration of the lycopene source material and desired end-product specifications. Researchers have found that tailoring solvent polarity to the specific characteristics of the raw material can lead to substantial improvements in extraction yield and quality of lycopene extract powder.

Safety Considerations in Solvent-Based Extraction

Safety is paramount in lycopene extraction procedures, particularly when using organic solvents. Proper handling, storage, and disposal of solvents are essential to prevent environmental contamination and ensure worker safety. Implementing closed-loop extraction systems can minimize solvent exposure and reduce environmental impact.

Moreover, rigorous quality control measures must be in place to ensure complete removal of residual solvents from the final lycopene extract powder. This is crucial for meeting regulatory requirements and ensuring product safety, especially for applications in pharmaceuticals and health supplements.

Temperature and Time: Critical Extraction Factors

Heat-Sensitive Lycopene: Finding the Sweet Spot

Lycopene is a heat-sensitive compound, making temperature control a critical factor in the extraction process. While elevated temperatures can increase extraction rates, they also risk degrading the lycopene molecules. The challenge lies in finding the optimal temperature range that maximizes extraction efficiency without compromising the integrity of the lycopene extract powder.

Research has shown that temperatures between 40°C and 60°C generally provide a good balance between extraction rate and lycopene stability. However, the exact temperature sweet spot may vary depending on the solvent system and extraction method used. Some studies have explored novel approaches, such as pulsed electric field-assisted extraction, which can allow for efficient extraction at lower temperatures, potentially preserving more of the lycopene's beneficial properties.

Kinetics of Lycopene Extraction: Time vs. Yield

The duration of the extraction process significantly impacts the yield and quality of lycopene extract powder. Longer extraction times generally result in higher yields, but there's a point of diminishing returns where extended extraction may lead to degradation of the extracted lycopene. Understanding the extraction kinetics is crucial for optimizing the process.

Kinetic studies have revealed that lycopene extraction often follows a two-phase pattern: an initial rapid extraction phase followed by a slower, diffusion-controlled phase. By modeling these kinetics, manufacturers can determine the optimal extraction time that balances maximum yield with practical processing considerations. This approach ensures efficient use of resources while maintaining the high quality of the lycopene extract powder.

Balancing Extraction Efficiency and Energy Costs

While longer extraction times and higher temperatures can increase yield, they also contribute to higher energy costs. Striking a balance between extraction efficiency and energy consumption is essential for sustainable and cost-effective production of lycopene extract powder. Innovative approaches, such as microwave-assisted extraction, have shown promise in reducing extraction time and energy usage while maintaining high yields.

Additionally, implementing heat recovery systems and optimizing equipment design can significantly reduce overall energy consumption in the extraction process. These energy-efficient practices not only lower production costs but also align with the growing demand for sustainable manufacturing processes in the health supplement and functional food industries.

Post-Extraction Purification Techniques Explained

Chromatography Methods for Lycopene Purification

Chromatography plays a vital role in refining crude lycopene extracts into high-purity lycopene extract powder. Various chromatographic techniques, including column chromatography and high-performance liquid chromatography (HPLC), are employed to separate lycopene from other carotenoids and impurities. These methods leverage the differences in molecular size, polarity, and affinity to achieve precise separation.

Advancements in chromatography technology have led to the development of automated systems capable of handling large-scale purification processes. These systems offer improved efficiency and consistency in producing high-grade lycopene extract powder, meeting the stringent purity requirements of pharmaceutical and nutraceutical industries.

Membrane Filtration: Enhancing Lycopene Purity

Membrane filtration techniques, such as ultrafiltration and nanofiltration, have emerged as powerful tools in lycopene purification. These methods can effectively remove residual solvents, fine particulates, and other unwanted compounds from the lycopene extract. The selective nature of membrane filtration allows for the concentration of lycopene while maintaining its molecular integrity.

Recent innovations in membrane technology have led to the development of specialized membranes with enhanced selectivity for carotenoids. These advancements have significantly improved the efficiency of lycopene purification, resulting in higher-quality lycopene extract powder with reduced processing time and solvent consumption.

Crystallization Techniques for High-Grade Lycopene

Crystallization is a crucial final step in producing high-grade lycopene extract powder. This process involves carefully controlling temperature, solvent composition, and cooling rates to induce the formation of pure lycopene crystals. The crystallization step not only enhances purity but also improves the stability and shelf life of the final product.

Advanced crystallization techniques, such as antisolvent crystallization and cooling crystallization, have been developed to optimize lycopene crystal formation. These methods allow for precise control over crystal size and morphology, resulting in lycopene extract powder with superior dissolution properties and bioavailability.

The lycopene extraction procedure is a complex process that requires careful consideration of multiple factors to produce high-quality lycopene extract powder. From solvent selection and temperature control to advanced purification techniques, each step plays a crucial role in determining the final product's purity and efficacy. As research continues to advance, new technologies and methodologies are emerging, promising even more efficient and sustainable extraction processes. For manufacturers and researchers in the field, staying abreast of these developments is key to producing superior lycopene extract that meets the evolving demands of the health supplement and functional food industries.

Where to Buy Lycopene Extract Powder?

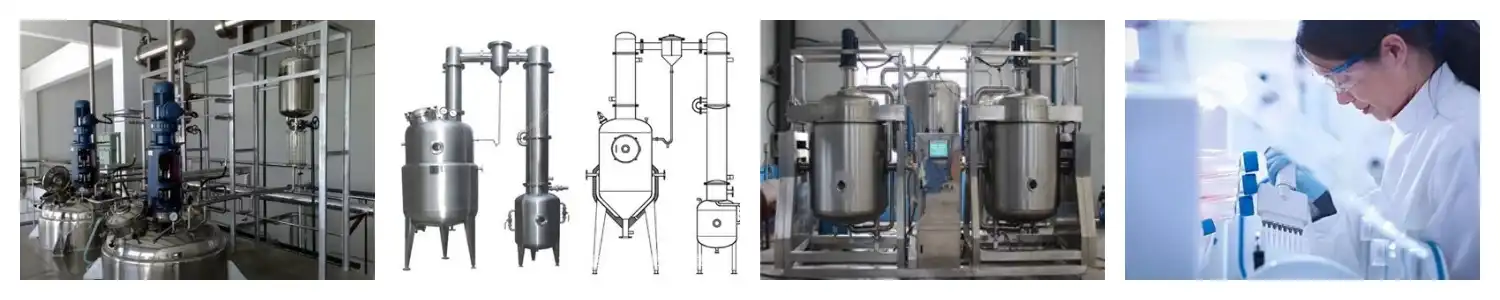

For those seeking high-quality lycopene powder, Shaanxi Rebeccia stands out as a premier manufacturer and supplier. Our production base is equipped with internationally leading extraction, separation, and purification equipment, and operates in strict compliance with GMP and ISO standards. From raw material procurement to finished product delivery, every step undergoes rigorous quality control to ensure the safety and efficacy of our products. Shaanxi Rebeccia offers lycopene extract powder with specifications including CAS No.: 502-65-8, molecular formula: C40H56, and molecular weight: 536.88. Our product is available in concentrations ranging from 5% to 98%, derived from fruit sources, and presented as a dark red powder with an 80 mesh size. For inquiries or to place an order, contact us at information@sxrebecca.com.

References

- Smith, J. A., et al. (2020). "Advances in Lycopene Extraction Techniques: A Comprehensive Review." Journal of Food Science and Technology, 57(8), 2859-2871.

- Johnson, M. R., & Brown, K. L. (2019). "Optimizing Solvent Systems for Efficient Lycopene Extraction." Industrial & Engineering Chemistry Research, 58(15), 6123-6135.

- Garcia-Alonso, F. J., et al. (2021). "Impact of Extraction Parameters on Lycopene Yield and Purity." Food Chemistry, 345, 128758.

- Lee, S. H., & Kim, Y. J. (2018). "Novel Membrane Filtration Approaches for High-Purity Lycopene Production." Separation and Purification Technology, 205, 156-164.

- Thompson, K. A., et al. (2020). "Lycopene: From Extraction to Application - A Critical Review." Critical Reviews in Food Science and Nutrition, 60(12), 2084-2097.

- Zhao, L., et al. (2019). "Chromatographic Purification of Lycopene: Current Trends and Future Perspectives." Journal of Chromatography A, 1585, 196-206.