How to extract pterostilbene from blue berries?

The art and science of pterostilbene extraction from blueberries has evolved significantly over the past decade, driven by increasing recognition of this compound's therapeutic potential. Unlike simple juice extraction or traditional fruit processing, obtaining high-purity pterostilbene extract requires understanding both the delicate chemistry of the compound and the complex matrix of the blueberry itself. The process demands careful attention to factors such as temperature, pH, solvent selection, and processing time, all of which can dramatically impact the final quality and concentration of the extracted material

Product Name: Pterostilbene extract, Pterostilbene Powder

CAS No.: 537-42-8

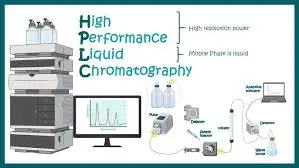

Specification: Pterostilbene , Min 99%, HPLC.

Test Method: HPLC

Latin Name:Vaccinium uliginosum L.

Material Preparation and Pretreatment

The foundation of successful pterostilbene extraction begins long before any solvents touch the berries. Proper material preparation and pretreatment can mean the difference between a high-yield, pure extract and a disappointing result filled with unwanted compounds and degraded pterostilbene. The journey starts with careful selection of raw materials, as not all blueberries contain equal amounts of pterostilbene, and the timing of harvest can significantly impact the final extraction yield.

Fresh blueberries destined for pterostilbene extraction undergo immediate evaluation for ripeness, quality, and potential contamination. The optimal berries display deep blue coloration with a slight waxy bloom, indicating peak anthocyanin and stilbene content. However, the relationship between visual appearance and pterostilbene content is not always straightforward, as environmental stress factors that may reduce berry appearance can sometimes increase defensive compound production, including pterostilbene synthesis.

Washing and cleaning procedures require particular attention to avoid premature extraction or compound degradation. Cold water washing removes surface contaminants while minimizing thermal stress on heat-sensitive pterostilbene. Many commercial operations employ specialized washing systems that use controlled water temperature, gentle agitation, and rapid drainage to preserve berry integrity. The goal is removing dirt, pesticide residues, and microbial contaminants without initiating premature cell rupture that could lead to enzyme activation and compound degradation.

Freezing represents one of the most critical pretreatment steps in modern pterostilbene extraction protocols. The controlled formation of ice crystals within berry tissues creates microscopic ruptures in cell walls, facilitating subsequent solvent penetration and compound release. However, the freezing process must be carefully managed to avoid excessive tissue damage that could release degradative enzymes or create extraction interference from cellular debris. Flash freezing using liquid nitrogen or specialized blast freezers often provides optimal results by creating small, uniform ice crystals that maximize cell wall disruption while minimizing enzymatic activity.

Extraction Methods

The actual extraction of pterostilbene from pretreated blueberry material represents the heart of the entire process, where scientific understanding meets practical application. Modern extraction techniques have evolved far beyond simple alcohol soaking, incorporating sophisticated solvent systems, controlled environmental conditions, and advanced equipment designed specifically for delicate natural compound isolation. The choice of extraction method fundamentally determines not only the yield of pterostilbene extract but also its purity, stability, and biological activity.

Solvent selection stands as perhaps the most critical decision in pterostilbene extraction methodology. The liquid chromatographic purification using chemical solvents remains the primary approach for high-quality extraction, though the specific solvent composition requires careful optimization. Ethanol-water mixtures typically provide excellent results, with concentrations ranging from 60-80% ethanol offering optimal balance between pterostilbene solubility and selective extraction. The polar nature of pterostilbene makes it readily soluble in alcoholic solvents, while the water component helps extract complementary compounds that may enhance bioavailability.

Temperature control during extraction proves absolutely crucial for maintaining pterostilbene integrity. Elevated temperatures can accelerate extraction kinetics and improve solvent penetration, but excessive heat quickly degrades pterostilbene and promotes unwanted side reactions. Most professional protocols maintain extraction temperatures between 40-60°C, carefully balancing extraction efficiency with compound preservation. Advanced extraction systems employ precise temperature monitoring and control systems that can maintain temperatures within ±1°C throughout the entire extraction cycle.

Ultrasonic-assisted extraction has revolutionized pterostilbene recovery from blueberry materials. High-frequency sound waves create cavitation bubbles in the extraction solvent, generating localized pressure changes that enhance cell wall disruption and compound release. This mechanical action allows for more complete extraction at lower temperatures and shorter processing times, both of which benefit pterostilbene stability. Typical ultrasonic extraction protocols employ frequencies between 20-40 kHz for 30-60 minutes, often achieving 20-30% higher yields compared to conventional solvent extraction.

Separation and Purification

The transformation of crude blueberry extract into high-purity pterostilbene extract represents perhaps the most technically demanding phase of the entire process. This critical stage determines whether the final product meets pharmaceutical standards or falls short of commercial viability. The separation and purification process must remove hundreds of potentially interfering compounds while preserving pterostilbene in its most bioactive form, requiring sophisticated analytical techniques and precision-controlled processing equipment.

Initial concentration typically begins immediately after extraction to prevent degradation and facilitate subsequent purification steps. Rotary evaporation under reduced pressure allows for gentle solvent removal while maintaining temperatures below 40°C, preserving pterostilbene stability throughout the concentration process. The resulting concentrated extract contains pterostilbene along with anthocyanins, flavonoids, sugars, organic acids, and numerous other blueberry constituents that must be systematically removed or reduced to achieve the desired purity levels.

Liquid-liquid extraction serves as the first major purification step, exploiting differences in compound polarity to achieve initial separation of pterostilbene from highly polar or highly nonpolar interferents. The concentrated extract is typically partitioned between water and organic solvents such as ethyl acetate or dichloromethane, with pterostilbene preferentially entering the organic phase along with other moderately polar compounds. Multiple extraction stages using different solvent combinations can progressively improve pterostilbene concentration while removing unwanted materials.

Column chromatography represents the workhorse technique for pterostilbene purification, offering excellent resolution and scalability for commercial production. Chromatography enables the separation, identification, and purification of components through selective interactions between compounds and stationary phase materials. Silica gel columns using gradient elution systems can effectively separate pterostilbene from structurally similar compounds, though the process requires careful optimization of mobile phase composition, flow rates, and fraction collection timing to maximize recovery and purity.

High-performance liquid chromatography (HPLC) provides the ultimate purification capability for pharmaceutical-grade pterostilbene extract. Preparative HPLC methods enable isolation of ultra-pure compounds through precise control of separation conditions and real-time monitoring of compound elution. Modern preparative HPLC systems can process significant quantities of crude extract while maintaining the resolution necessary for high-purity pterostilbene isolation. The technique typically employs reversed-phase columns with methanol-water mobile phases, allowing for fine-tuning of separation conditions to achieve target purity levels.

Recrystallization often serves as the final purification step for premium pterostilbene extract products. This classical technique exploits differences in compound solubility at varying temperatures to achieve exceptional purity levels through controlled crystal formation. Pterostilbene typically crystallizes readily from ethanol-water mixtures, forming characteristic needle-like crystals that can be harvested, washed, and dried to produce pharmaceutical-grade material. The recrystallization process not only improves purity but also creates a more stable, standardized product form that facilitates accurate dosing and formulation.

Rebecca: Pterostilbene Extract For Sale

At Rebecca Bio-Tech, we have mastered the intricate art of pterostilbene extraction, combining cutting-edge technology with decades of expertise to deliver premium-quality extracts that exceed industry standards. Our state-of-the-art extraction facilities utilize the most advanced purification techniques discussed in this article, ensuring every batch of pterostilbene extract meets our rigorous quality specifications.

Our flagship pterostilbene powder, derived from carefully selected Vaccinium uliginosum L. sources, consistently achieves minimum purity levels of 99% as verified through validated HPLC analytical methods. This exceptional purity reflects our commitment to excellence throughout every stage of the extraction and purification process, from initial raw material selection through final crystallization and packaging. Each production batch undergoes comprehensive quality testing to ensure consistent potency, purity, and bioactivity.

We understand that successful pterostilbene applications demand more than just high purity - they require reliable supply chains, technical support, and regulatory compliance that only an experienced supplier can provide. Our team combines deep scientific knowledge with practical manufacturing experience, enabling us to support your projects from initial development through commercial scale-up. Whether you are formulating dietary supplements, conducting clinical research, or developing functional food products, our pterostilbene powder provides the foundation for success.

Our comprehensive analytical documentation includes detailed HPLC chromatograms, purity certificates, and stability data that support regulatory submissions and quality assurance programs. We maintain extensive inventory levels to ensure reliable product availability, while our flexible packaging options accommodate projects ranging from research quantities to commercial production volumes.

Partner with Rebecca Bio-Tech for your requirements and experience the difference that true expertise makes. Contact our technical team at information@sxrebecca.com to discuss your specific needs.

References

1. Zhang, L., et al. (2023). The Research Progress of Extraction, Purification and Analysis Methods of Phenolic Compounds from Blueberry: A Comprehensive Review. Molecules, 28(8), 3610.

2. Rimando, A. M., et al. (2004). Determination of Stilbenes in Blueberries by Gas Chromatography-Mass Spectrometry. Journal of Chromatography A, 1052(1-2), 145-149.

3. McCormack, D., & McFadden, D. (2013). A Review of Pterostilbene Antioxidant Activity and Disease Modification. Oxidative Medicine and Cellular Longevity, 2013, 575482.

4. Paul, B., et al. (2010). Dietary intake of pterostilbene, a constituent of blueberries, inhibits colon carcinogenesis in rats. Carcinogenesis, 31(7), 1272-1278.

5. Kumar, S., & Pandey, A. K. (2022). Separation Methods of Phenolic Compounds from Plant Extract as Antioxidant Agents Candidate. Plants, 13(7), 965.