Is chitosan an oligosaccharide?

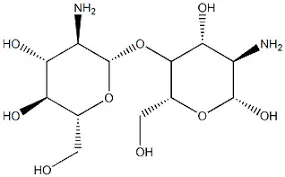

chitosan oligosaccharide powder, a derivative of chitosan, is indeed classified as an oligosaccharide. This unique compound is formed through the depolymerization of chitosan, resulting in shorter chain molecules that retain the beneficial properties of chitosan while offering enhanced solubility and bioavailability. As a low molecular weight version of chitosan, it falls within the oligosaccharide category, typically consisting of 2-10 monosaccharide units.

Chitosan Oligosaccharide Powder

Product Name:Chitosan oligosaccharide

Assay: 90% 95% 99%

CAS No.: 148411-57-8

Molecular Formula: C12H24N2O9

Appearance: Light yellow powder

Grade: Medicine/Food/Cosmetic/Agricultural/ Feed Grade

Defining oligosaccharides: Where chitosan fits in

Understanding oligosaccharides: A brief overview

Oligosaccharides are carbohydrates composed of a small number of monosaccharide units, typically ranging from 2 to 10. These compounds play crucial roles in various biological processes and are found naturally in many foods. Oligosaccharides are known for their prebiotic properties, supporting gut health and immune function. They occupy a unique position in the carbohydrate family, being larger than simple sugars but smaller than polysaccharides.

Chitosan's classification in the oligosaccharide family

Chitosan, when broken down into smaller units, forms chitosan oligosaccharides. These molecules retain the basic structure of chitosan but with a significantly reduced molecular weight. This transformation places chitosan oligosaccharides firmly within the oligosaccharide category. The process of creating chitosan oligosaccharide powder involves controlled depolymerization, resulting in chains that typically contain 2-10 glucosamine units. This classification is crucial for understanding the compound's behavior in biological systems and its potential applications.

Comparing chitosan to other common oligosaccharides

While chitosan oligosaccharides share the general characteristics of oligosaccharides, they possess unique properties that set them apart. Unlike many plant-based oligosaccharides such as fructooligosaccharides or galactooligosaccharides, chitosan oligosaccharides are derived from animal sources, primarily crustacean shells. This origin gives them distinct chemical properties, including a positive charge in acidic conditions. Compared to other oligosaccharides, chitosan derivatives often exhibit stronger antimicrobial and wound-healing properties, making them valuable in pharmaceutical and biomedical applications.

Chitosan's molecular structure: A closer look

Chitosan's unique chemical composition

Chitosan oligosaccharide powder possesses a distinctive chemical structure that contributes to its diverse applications. At its core, chitosan is a linear polysaccharide composed of β-(1,4)-linked D-glucosamine and N-acetyl-D-glucosamine units. When transformed into oligosaccharides, these chains are shortened, but the fundamental building blocks remain the same. The presence of amino groups along the chain imparts a positive charge to chitosan oligosaccharides in acidic environments, a feature that sets them apart from many other oligosaccharides and contributes to their unique properties.

The role of deacetylation in chitosan formation

The process of deacetylation is crucial in the transformation of chitin into chitosan and, subsequently, into chitosan oligosaccharide powder. During deacetylation, acetyl groups are removed from the chitin molecule, increasing the number of free amino groups. The degree of deacetylation significantly influences the properties of the resulting chitosan and its oligosaccharides. Higher degrees of deacetylation generally lead to increased solubility and reactivity, which are desirable qualities in many applications. The precise control of this process is essential in producing high-quality chitosan oligosaccharide powder with consistent properties.

Chitosan's structure influences its properties

The unique structure of chitosan oligosaccharides directly influences their functional properties. The presence of free amino groups allows for interactions with various molecules, contributing to their antimicrobial, antioxidant, and chelating abilities. The shortened chain length of oligosaccharides, compared to full-length chitosan, enhances their solubility and bioavailability. This improved solubility is particularly beneficial in formulations for nutraceuticals and functional foods. Additionally, the cationic nature of chitosan oligosaccharides in acidic conditions facilitates their interaction with negatively charged surfaces, including cell membranes, which is crucial for their biological activities.

From chitin to chitosan: The transformation process

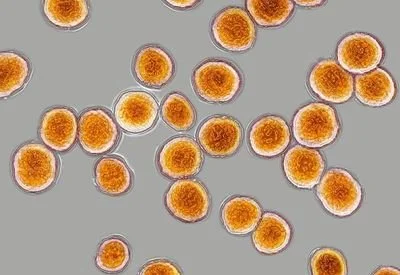

Chitin sources: Crustacean shells and fungal cell walls

The journey of chitosan oligosaccharide powder begins with its precursor, chitin. Chitin is abundantly found in nature, primarily in the exoskeletons of crustaceans such as shrimp, crabs, and lobsters. It's also present in the cell walls of fungi. The choice of chitin source can impact the final properties of the chitosan oligosaccharide. Crustacean shells are the most common commercial source due to their availability as a byproduct of the seafood industry. However, fungal sources are gaining attention, especially for applications requiring non-animal-derived ingredients.

Deacetylation methods: Chemical vs. enzymatic approaches

The transformation of chitin into chitosan involves deacetylation, which can be achieved through chemical or enzymatic methods. Chemical deacetylation typically uses strong alkaline conditions and high temperatures, offering efficiency and scalability. Enzymatic deacetylation, on the other hand, employs specific enzymes to remove acetyl groups under milder conditions. While enzymatic methods can provide more controlled and environmentally friendly processes, they are often more expensive and time-consuming. The choice between these methods depends on factors such as desired product characteristics, scale of production, and environmental considerations.

Quality control in chitosan oligosaccharide powder production

Ensuring the quality and consistency of chitosan oligosaccharide powder is crucial for its applications in various industries. Quality control measures focus on several key parameters, including molecular weight distribution, degree of deacetylation, and purity. Advanced analytical techniques such as high-performance liquid chromatography (HPLC) and nuclear magnetic resonance (NMR) spectroscopy are employed to characterize these properties accurately. Stringent quality control processes also involve testing for contaminants, including heavy metals and microbial presence. Adherence to good manufacturing practices (GMP) and international quality standards is essential in producing pharmaceutical and food-grade chitosan oligosaccharides.

Chitosan oligosaccharide powder, derived from the depolymerization of chitosan, is indeed classified as an oligosaccharide. Its unique structure, combining the benefits of chitosan with enhanced solubility and bioavailability, makes it a valuable ingredient in various industries. From its origins in crustacean shells to its carefully controlled production process, chitosan oligosaccharide represents a fascinating intersection of natural sourcing and advanced processing technologies. Its diverse applications in pharmaceuticals, nutraceuticals, and functional foods underscore its importance as a versatile oligosaccharide with significant potential for future innovations.

China Chitosan Oligosaccharide Powder Supplier

Shaanxi Rebeccia stands at the forefront of production, offering high-quality products tailored to meet diverse industry needs. Our state-of-the-art production facility employs cutting-edge extraction, separation, and purification technologies, ensuring the highest standards of product quality and consistency. Operating under strict GMP and ISO guidelines, we maintain rigorous quality control throughout our production process, from raw material sourcing to final product delivery. Our chitosan oligosaccharide powder, available in various grades including 90%, 95%, and 99% purity, caters to pharmaceutical, food, cosmetic, agricultural, and feed industries. To learn more about our premium chitosan oligosaccharide or to discuss your specific requirements, contact us at information@sxrebecca.com.

References

- Zhang, L., & Zhao, Q. (2020). Chitosan oligosaccharides: Biological activities and potential therapeutic applications. Marine Drugs, 18(5), 262.

- Naveed, M., et al. (2019). Chitosan oligosaccharide (COS): An overview. International Journal of Biological Macromolecules, 129, 827-843.

- Muanprasat, C., & Chatsudthipong, V. (2017). Chitosan oligosaccharide: Biological activities and potential therapeutic applications. Pharmacology & Therapeutics, 170, 80-97.

- Zou, P., et al. (2016). Advances in characterisation and biological activities of chitosan and chitosan oligosaccharides. Food Chemistry, 190, 1174-1181.

- Liaqat, F., & Eltem, R. (2018). Chitooligosaccharides and their biological activities: A comprehensive review. Carbohydrate Polymers, 184, 243-259.

- Xia, W., et al. (2011). Biological activities of chitosan and chitooligosaccharides. Food Hydrocolloids, 25(2), 170-179.