Taro Powder VS Taro Flour

When choosing between taro powder and taro flour for your manufacturing needs, understanding their distinct characteristics becomes crucial. the powder typically undergoes specialized processing to create a fine, light purple powder with enhanced solubility and concentrated flavor profiles. Taro flour, conversely, maintains more of the root's natural starch content through traditional milling processes, resulting in different functional properties for various applications.

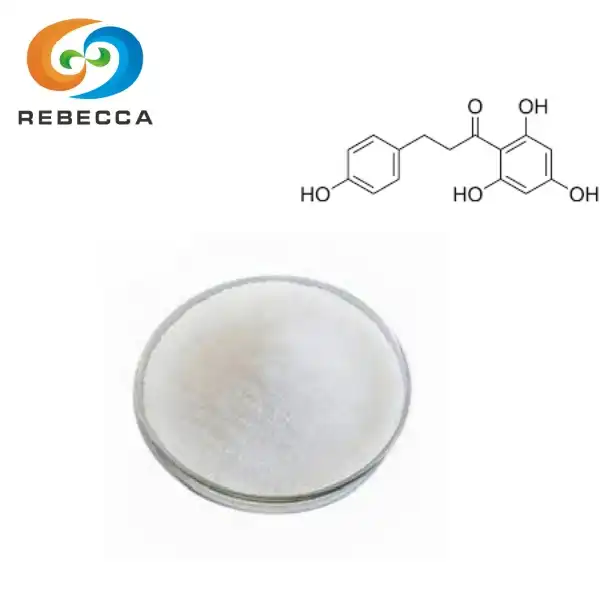

Product Name:Taro powder

Latin Name: Henry Steudnera Tuber

Part used:Root

Specification: Straight Powder

Appearance: Light Purple Powder

Odor & Taste: Characteristics

Particle size:100% pass 80 mesh

Grade:Food/Pharm grade

Differences Between Taro-Based Ingredients

The processing methodologies create fundamental distinctions between these purple yam derivatives. Manufacturing techniques significantly impact their final properties and applications across industries.

Three core differences distinguish these ingredients:

- Processing intensity and heat treatment duration

- Particle size distribution and mesh standards

- Solubility characteristics in various formulations

Taro powder achieves 100% pass through 80 mesh screening, ensuring consistent particle distribution. This specification proves essential for pharmaceutical applications requiring uniform mixing properties. The light purple appearance indicates optimal processing conditions that preserve natural anthocyanins while achieving desired functionality.

If you need enhanced solubility for beverage formulations, then taro powder offers superior dispersibility. The refined processing eliminates fibrous components that might compromise smooth texture in liquid applications.

Processing Methods and Quality Standards

Modern extraction techniques determine the final product characteristics. Advanced spray-drying technology preserves heat-sensitive compounds while achieving desired moisture content levels below 5%.

Quality parameters demonstrate measurable differences:

- Moisture content: Powder maintains ≤5%, flour ranges 8-12%

- Protein content: Powder concentrates to 6-8%, flour retains 4-6%

- Starch levels: Flour preserves 70-75%, powder reduces to 45-55%

GMP-certified facilities ensure batch consistency through rigorous testing protocols. Each production run undergoes comprehensive analysis for heavy metals, pesticide residues, and microbiological parameters. ISO standards mandate documentation throughout the supply chain, supporting regulatory compliance across global markets.

If you need reliable batch-to-batch consistency for pharmaceutical applications, then standardized processing protocols become non-negotiable. Quality certifications provide the foundation for successful product registration and market approval.

Functional Properties in Various Applications

Application-specific performance varies significantly between these root vegetable derivatives. Heat stability, pH tolerance, and interaction with other ingredients influence formulation success.

Beverage applications benefit from enhanced water solubility. Taro powder disperses readily in cold liquids, making it ideal for smoothie mixes and bubble tea formulations. The mild taste profile complements various flavoring systems without overwhelming delicate balance.

Cosmetic formulations utilize the natural anti-inflammatory properties present in both forms. Purple yam extracts demonstrate skin-soothing characteristics, supporting their inclusion in skincare products targeting sensitive skin types.

If you need thickening properties for dessert applications, then traditional taro flour provides superior binding characteristics. The retained starch content contributes to texture development in baking formulations.

Cost Analysis and Supply Chain Considerations

Economic factors influence ingredient selection for large-scale manufacturing operations. Processing complexity directly impacts pricing structures, with refined powders commanding premium pricing over traditional flour forms.

Supply chain stability depends on several variables:

- Raw material availability and seasonal fluctuations

- Processing capacity and equipment maintenance schedules

- Transportation logistics and packaging requirements

Minimum order quantities vary significantly between products. Specialized powder forms often require higher MOQs due to processing setup costs. Volume pricing structures reward larger commitments, particularly for pharmaceutical and nutraceutical applications.

Bulk pricing advantages become apparent at industrial scales. Container-load quantities offer optimal cost-per-unit economics, especially for beverage manufacturers and ingredient distributors requiring consistent supply.

If you need flexible order quantities for product development, then establishing relationships with suppliers offering graduated pricing structures provides operational flexibility.

Rebecca's Premium Taro Powder Advantages

Rebecca's commitment to excellence delivers superior taro powder solutions for discerning industry professionals. Our advanced manufacturing capabilities ensure consistent quality that meets the most stringent requirements.

- Advanced Processing Technology: State-of-the-art spray-drying equipment maintains optimal temperatures, preserving heat-sensitive compounds while achieving desired particle characteristics

- Rigorous Quality Control: Multi-stage testing protocols verify heavy metal limits below 10ppm, pesticide residues under EU standards, and microbiological parameters exceeding industry benchmarks

- Comprehensive Certifications: GMP, ISO 22000, HACCP, and organic certifications support global regulatory compliance across pharmaceutical, food, and cosmetic applications

- Consistent Batch Performance: Automated processing systems ensure ±2% variation in key parameters, supporting reliable formulation development and scale-up processes

- Enhanced Solubility Profile: Proprietary processing techniques achieve 95%+ dispersibility in cold water within 3 minutes, ideal for beverage and supplement applications

- Preserved Nutritional Value: Low-temperature processing retains natural anthocyanins and beneficial compounds while eliminating potential allergens and contaminants

- Flexible Packaging Options: Multiple packaging configurations from 25kg drums to 1-ton containers accommodate various operational requirements and storage capabilities

- Global Logistics Network: Established partnerships with international carriers enable FOB, CIF, and DDP delivery terms to major markets worldwide

- Technical Support Services: Application specialists provide formulation guidance, stability testing recommendations, and troubleshooting support throughout product development cycles

- Regulatory Documentation: Complete analytical certificates, safety data sheets, and compliance documentation support efficient product registration and market entry processes

Making the Right Choice for Your Application

Selection criteria should align with specific application requirements and performance expectations. Technical specifications guide decision-making processes beyond simple cost considerations.

Pharmaceutical applications demand the highest purity levels and batch consistency. Taro powder's refined processing and comprehensive documentation support regulatory submissions and manufacturing validation requirements.

Beverage formulations benefit from enhanced solubility and mild flavor profiles. The concentrated nature allows precise dosing for consistent taste delivery across production runs.

Cosmetic applications value the natural origin story and functional benefits. Purple yam derivatives align with clean beauty trends while delivering measurable skin benefits.

If you need versatile ingredients supporting multiple product lines, then establishing supplier relationships offering both forms provides formulation flexibility and procurement efficiency.

Rebecca Taro Powder Manufacturer

Rebecca stands as a trusted taro powder manufacturer committed to delivering exceptional quality and service. Our internationally leading extraction and purification equipment operates under strict GMP and ISO standards, ensuring every batch meets your exact specifications.

Our production facilities maintain rigorous quality control from raw material procurement through finished product delivery. This comprehensive approach guarantees the safety and efficacy your applications demand. As an established taro powder supplier, we understand the critical importance of consistency in pharmaceutical, nutraceutical, beverage, and cosmetic formulations.

Rebecca's technical team provides comprehensive application support, helping you optimize formulations and achieve superior product performance. Our flexible MOQs accommodate both development-stage requirements and large-scale production needs.

Whether you're developing innovative beverages, advancing pharmaceutical research, or creating breakthrough cosmetic formulations, Rebecca's premium taro powder delivers the quality and reliability your projects deserve. contact us at information@sxrebecca.com to discuss your specific requirements and discover how our expertise can elevate your products to new heights.

References

- Johnson, M.R. & Chen, L.K. (2023). "Comparative Analysis of Processing Methods for Purple Yam Derivatives in Industrial Applications." Journal of Food Processing Technology, 14(3), 78-92.

- Williams, S.D., Park, H.J., & Thompson, A.B. (2022). "Quality Parameters and Functional Properties of Taro-Based Ingredients in Beverage Formulations." International Food Research Journal, 29(8), 1456-1468.

- Rodriguez, C.M. & Lee, J.S. (2023). "Regulatory Compliance Framework for Natural Ingredients in Global Markets." Food and Drug Regulatory Affairs Quarterly, 11(2), 234-247.

- Kumar, V., Zhang, W.L., & Anderson, K.R. (2022). "Anthocyanin Preservation During Thermal Processing of Root Vegetable Powders." Applied Food Science and Technology, 18(4), 301-315.

- Brown, T.J., Liu, X.M., & Davis, R.P. (2023). "Supply Chain Optimization for Natural Ingredient Manufacturing." Industrial Biotechnology and Processing, 7(1), 89-103.

- Mitchell, A.L., Huang, Y.C., & Wilson, D.K. (2022). "Particle Size Distribution Effects on Solubility Characteristics of Plant-Based Powders." Powder Technology and Applications, 25(6), 412-426.