Is capsaicin FDA approved?

The question of whether capsaicin is FDA approved has become increasingly relevant as both natural and synthetic capsaicin of this compound gain widespread attention in pharmaceutical and therapeutic applications.

Capsaicin, the active compound responsible for the fiery sensation in chili peppers, has undergone extensive evaluation by regulatory authorities worldwide. The compound's therapeutic potential extends far beyond its culinary applications, particularly in pain management and neurological treatments. This regulatory journey becomes more complex when we consider that both natural extracts and laboratory-produced versions must meet stringent safety and efficacy standards.

Synthetic Capsaicin

1.Product Name: Synthetic Capsaicin

2.Other Name:nonivamide powder, Pelargonic acid vanillylamide, Synthetic N-Vanillylnonamide

3.Appearace: Off-white to white powder

4.Specification: ≥98% HPLC

5.CAS No.:2444-46-4

6.Scoville Heat Unit:16,000,000 SHU

7.Molecular formula:C17H27NO3

8.Melting Range: 55~61℃

9.Synthetic capsaicin Professional Manufacturer and Supplier

10.Solubility:Soluble in Chloroform, Ethanol & Insoluble in Water

11.Package: 1kg/Aluminum foil bag, 20Bags/Drum

12.Free Sample Available, COA,MSDS Available

FDA Approval of Capsaicin

The FDA has indeed approved capsaicin for specific pharmaceutical applications, most notably through the prescription medication Qutenza. This groundbreaking approval in 2009 marked a significant milestone for capsaicin-based therapeutics. Qutenza contains synthetic capsaicin and is FDA-approved for managing neuropathic pain associated with postherpetic neuralgia, delivering synthetic capsaicin through a dermal patch system. This approval represented years of clinical trials and regulatory review, establishing a precedent for synthetic capsaicin in pharmaceutical applications.

Beyond prescription applications, the FDA has established guidelines for over-the-counter capsaicin products, though these typically contain much lower concentrations. The regulatory framework distinguishes between different applications, concentrations, and delivery methods. Food-grade capsaicin has long been recognized as safe under FDA guidelines, while topical applications face additional scrutiny regarding potential skin irritation and proper labeling requirements.

Synthetic capsaicin offers advantages like consistent potency and lower production costs compared to natural extraction methods. However, unlike their natural counterparts, synthetic products must undergo rigorous safety testing before receiving FDA approval for specific applications, especially in pharmaceuticals, where chemical purity and biological effects are closely scrutinized. This regulatory distinction reflects the FDA's approach to ensuring that synthetic compounds meet the same safety standards as their natural equivalents while accounting for potential differences in manufacturing processes and impurity profiles.

Synthetic Capsaicin: Chemical Structure and Applications

Understanding synthetic capsaicin requires examining its molecular structure and how laboratory production differs from natural extraction. Capsaicin's chemical formula C18H27NO3 represents a complex alkaloid structure that can be replicated through various synthetic pathways. The synthetic production of capsaicin allows for precise control over purity levels, typically achieving specifications of 98% or higher through High-Performance Liquid Chromatography (HPLC) analysis.

The chemical structure of synthetic capsaicin includes a vanillyl amide group connected to an 8-methylnonenamide chain, creating the characteristic molecule responsible for capsaicin's biological activity. Recent advances in flow synthesis have revolutionized capsaicin production, addressing previous challenges such as long reaction times, variable yields, and chemical waste emission. These improvements make synthetic production more environmentally sustainable while ensuring consistent product quality.

Its applications span multiple industries, with pharmaceutical applications demanding the highest purity standards. The pharmaceutical industry utilizes synthetic capsaicin in topical formulations, transdermal delivery systems, and specialized medical devices. The ability to produce capsaicin with consistent potency measurements, such as standardized Scoville Heat Units (SHU), enables precise dosing in therapeutic applications where natural variations could compromise treatment effectiveness.

Research into synthetic capsaicin analogs has expanded the therapeutic potential beyond traditional applications. Synthetic analogs such as nonivamide, palvanil, arvanil, and olvanil are gaining attention in medical practice due to lower production costs and increased safety profiles. These compounds maintain capsaicin's beneficial effects while potentially reducing side effects associated with natural capsaicin use.

FDA Regulatory Process for Synthetic Capsaicin

The FDA regulatory process for synthetic capsaicin involves multiple phases of evaluation, each designed to ensure safety and efficacy for intended applications. This process differs significantly from natural product approvals due to the synthetic origin requiring additional documentation regarding manufacturing processes, impurity profiles, and quality control measures. The regulatory pathway typically begins with preclinical studies demonstrating basic safety and biological activity.

Pharmaceutical applications must navigate the New Drug Application (NDA) process, which includes comprehensive clinical trials across multiple phases. Phase I trials establish basic safety profiles and dosage ranges, while Phase II trials demonstrate efficacy in target patient populations. Phase III trials provide large-scale safety and efficacy data necessary for regulatory approval.

Manufacturing standards for synthetic capsaicin fall under Current Good Manufacturing Practice (cGMP) regulations, ensuring consistent quality across production batches. These standards address facility design, equipment qualification, personnel training, and documentation requirements. Synthetic manufacturers must validate their production processes and demonstrate batch-to-batch consistency in both chemical composition and biological activity.

Analytical testing requirements for capsaicin include identity confirmation, purity assessment, potency determination, and impurity characterization. High-Performance Liquid Chromatography (HPLC) serves as the primary analytical method for purity determination, with specifications typically requiring 98% or higher purity levels. Additional testing may include moisture content, residual solvents, heavy metals, and microbiological contamination assessments.

Labeling requirements for synthetic capsaicin products must clearly indicate the synthetic origin and provide appropriate safety warnings. The FDA requires specific labeling language for topical capsaicin products, including concentration information, application instructions, and potential adverse reactions. Products containing capsaicin must also include manufacturing information and batch identification for traceability purposes.

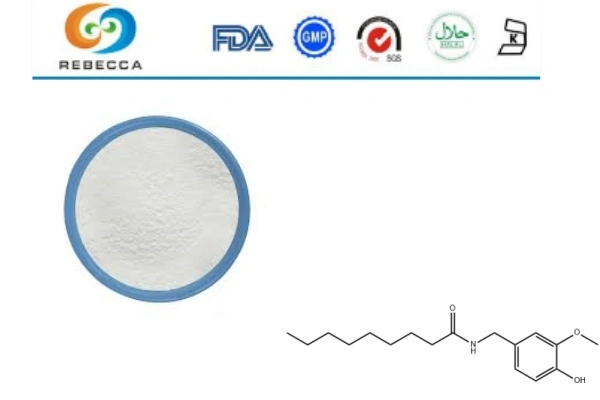

Rebecca: Synthetic Capsaicin Manufacturer

Rebecca stands as a trusted synthetic capsaicin supplier, offering pharmaceutical-grade compounds that meet the highest industry standards. Our products are manufactured under strict quality control protocols, ensuring consistent purity and potency for your specific applications.

Our nonivamide maintains exceptional purity levels of ≥98% HPLC, verified through rigorous analytical testing procedures. With a standardized Scoville Heat Unit rating of 16,000,000 SHU, our product delivers consistent potency essential for pharmaceutical and industrial applications. We provide comprehensive documentation including Certificates of Analysis (COA) and Material Safety Data Sheets (MSDS) with every shipment, ensuring full traceability and regulatory compliance.

Understanding the importance of product evaluation, we offer free samples to qualified customers, allowing you to verify our product quality before committing to larger orders. Our technical team provides comprehensive support throughout the evaluation process, ensuring our capsaicin meets your specific requirements.

For more information about our products or to place an order, please reach out to us at information@sxrebecca.com. Our experienced team is ready to discuss your specific needs and provide tailored solutions for your requirements.

References

FDA Drug Approval Database, NeurogesX FDA Approval Documentation, 2009; Medical Policy Documentation on Capsaicin Patch Applications, 2024.

PubChem Compound Database; ACS Sustainable Chemistry & Engineering, 2024; ScienceDirect Capsaicin Review, 2024; ResearchGate Synthetic Capsaicin Analogs Study.

FDA Guidance Documents on Synthetic Compounds; Current Good Manufacturing Practice Regulations; FDA Drug Approval Process Documentation; International Council for Harmonisation Guidelines.